Coating, Assembly and logistics

Making Sure Protection Sticks Together!

Seamlessly integrated processes, managed to ensure precise application that meet the highest standards of quality and performance.

Our coating methods deliver durable and high-quality finishes, while our efficient assembly processes ensure precise and timely product integration. We focus on protective and aesthetic coatings and expertly assembled products, consistently meeting quality standards and delivery deadlines.

Pre-Treatment Line:

We have a 7-tank pre-treatment system with an automated transporter that handles MS, GI, and AL materials up to 2700 mm long and 700 mm wide.

Powder Coating:

We operate an automated conveyorized plant with a Mitsuba cartridge system and 6 reciprocator guns for fast powder changes. A semi-auto conveyorized system handles batch production in various colors. Capable of coating MS, SS, aluminum, and GI. The facility processes up to 50,000 square feet daily.

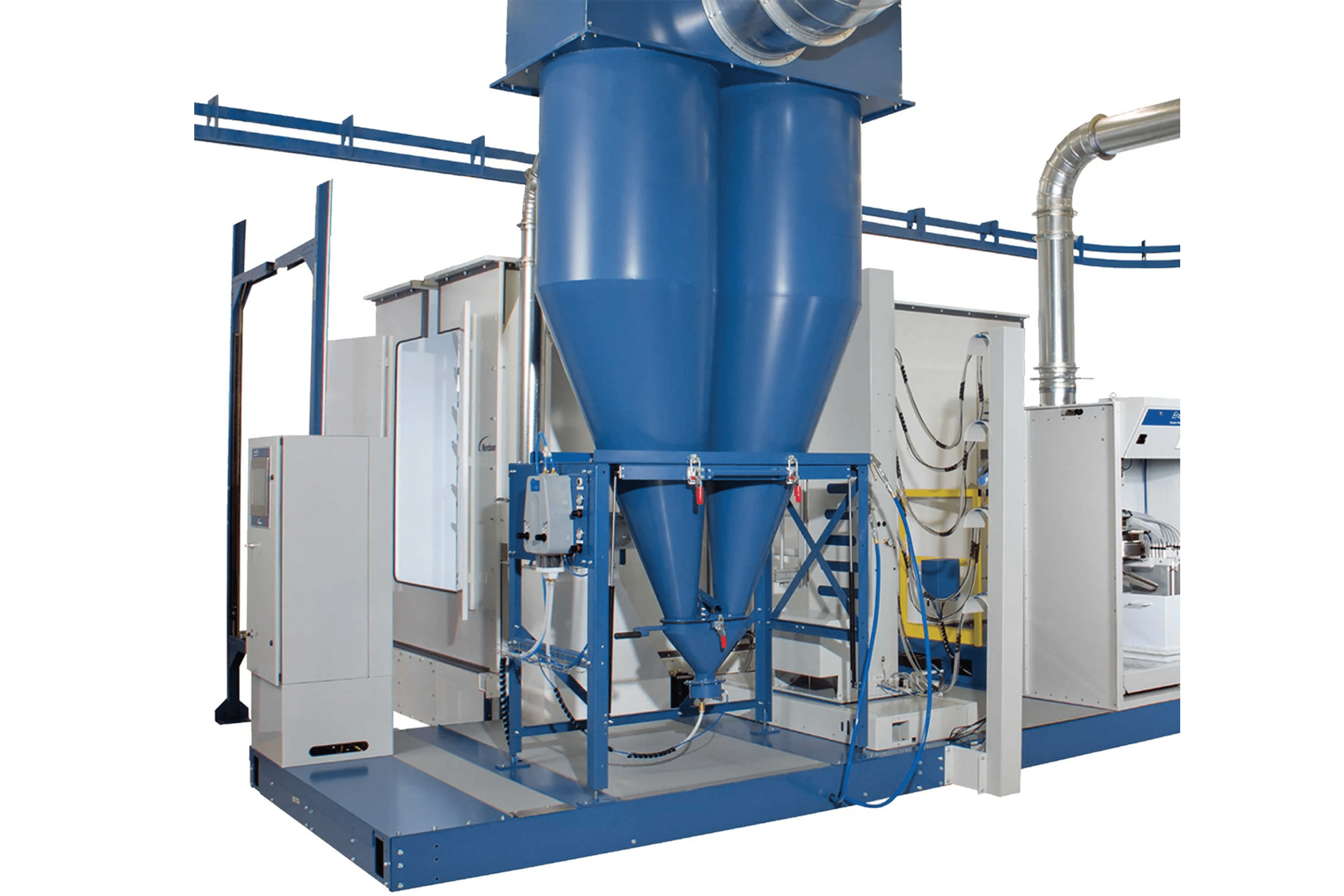

Blasting:

Our blasting setup includes fully automatic dust recovery, achieving SA2 half surface finish for optimal paint adhesion.

Painting:

In-house painting is done with airless spray guns, using synthetic enamel, epoxy, and PU paints. We apply quick-dry DTM and primer coatings, including zinc-based primers and top-coat PU finishes.

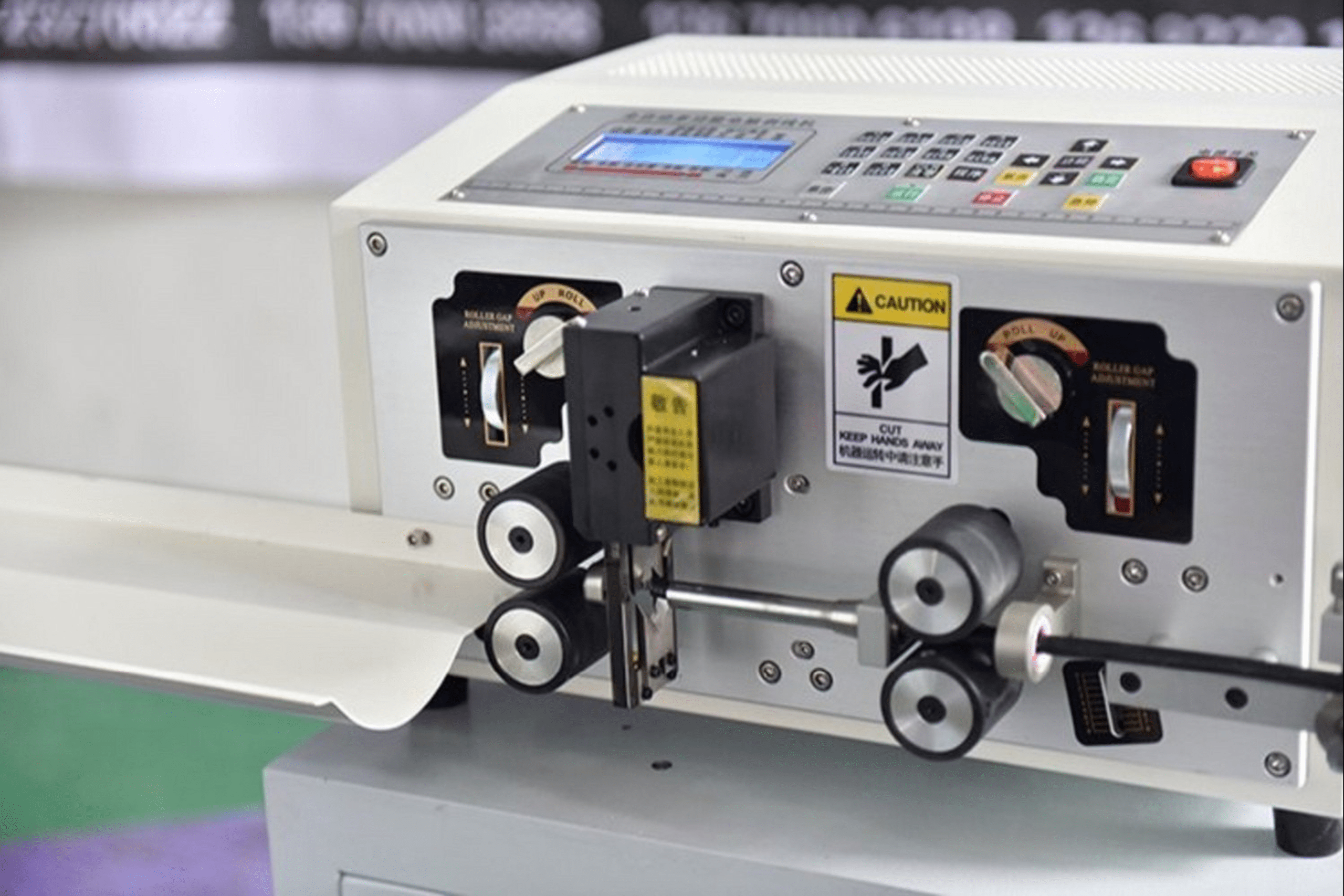

Assembly:

Assembly with advanced pneumatic tools, ensuring high-speed, precise production. We utilize Pneumatic Screwdrivers for rapid and accurate fastening, Pneumatic Tapping Machines for meticulous threading, and Pneumatic Riveting Machines for robust joining of components. For dispatch, we provide custom packing solutions that safeguard products during transport. Our tailored packaging optimizes space and minimizes damage risk, ensuring secure and efficient delivery. Together, our assembly and packing services streamline production and enhance product reliability.

Logistics:

Steelsmith Continental is strategically located in Vadodara, positioned in the east-central part of Gujarat, India. This advantageous geographic location provides excellent connectivity to major logistics hubs. Gujarat boasts the longest coastline in India, and Vadodara, being proximate to Maharashtra, further enhances access to additional coastal resources. This proximity to Maharashtra grants access to several international shipping ports, greatly benefiting our operations. Gujarat and Maharashtra’s extensive coastline plays a crucial role in enhancing shipping and logistics capabilities. Gujarat’s coastline, spanning approximately 1600 kilometers, is dotted with several major ports such as Kandla, Mundra, and Dahej, among others, which are pivotal in facilitating international trade and shipping activities. Similarly, Maharashtra’s coastline, including ports like Mumbai and Nhava Sheva, further complements these logistical advantages. Due to these strategic advantages, our company benefits from significantly reduced sailing times, typically ranging between 30 to 60 days under favorable conditions. This robust logistical infrastructure ensures efficient operations and enhances our competitiveness in the global market.