Fabrication and Forming

Shaping Strength!

Meticulously executed to produce high-quality components that meet rigorous industry standards and client specifications

Our journey begins with design, followed by precise CNC and Press operations, ensuring every component meets exact specifications.

But our commitment doesn’t end there. Once material is moved to our Fabrication Department, it undergoes transformation. Our arsenal includes the latest equipment operated by skilled technicians, ensuring unparalleled accuracy and efficiency.

From cutting and bending to welding and finishing, each step is executed to deliver products of the highest quality. With our dedication to excellence and technology, you can trust Steelsmith Continental for all your fabrication needs. Experience the difference precision makes.

Welding:

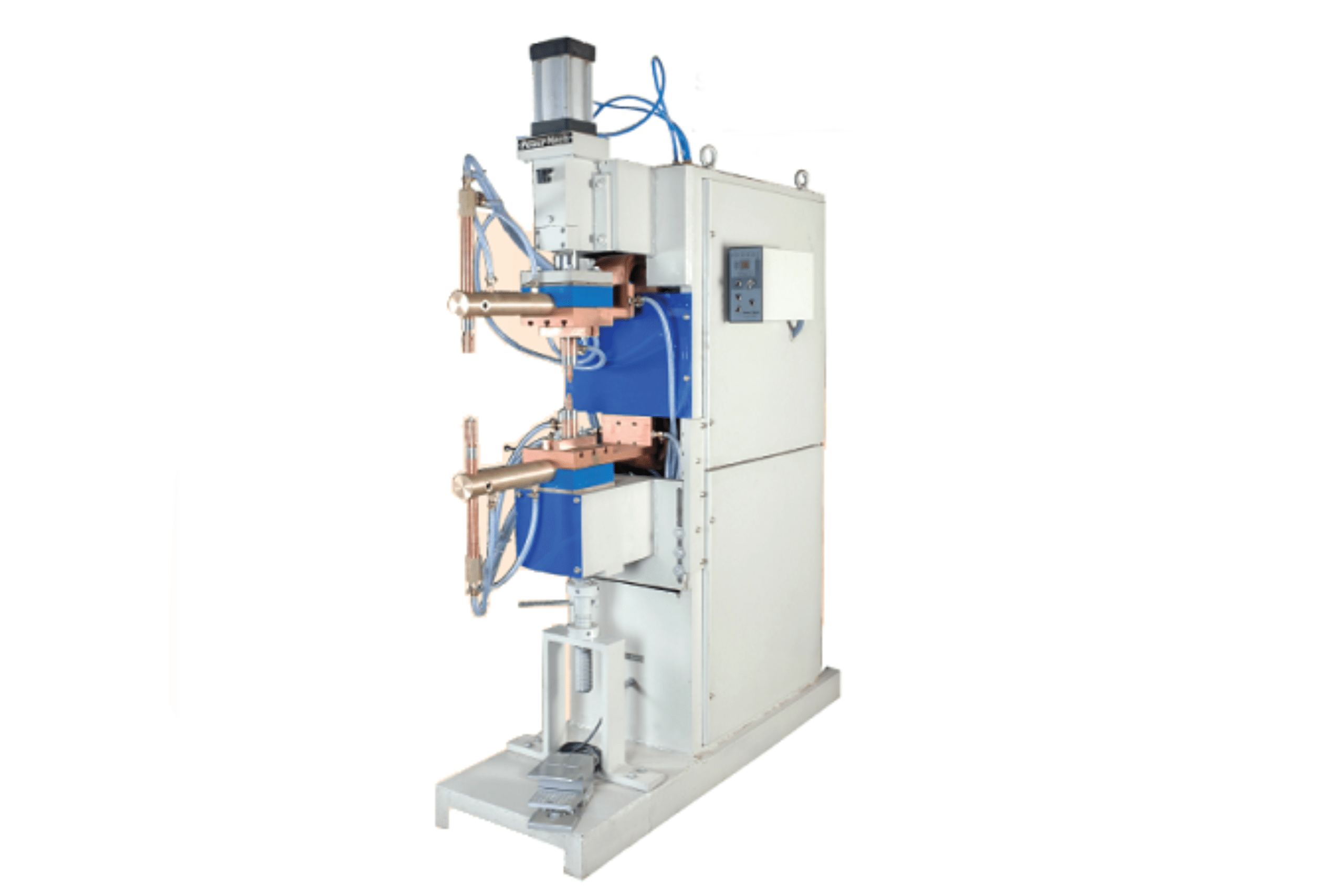

Metal joining with advanced welding technologies and precision equipment. We use MIG for efficient mild steel welding and TIG for precise stainless steel and aluminum welds. Our projection spot and stud welding machines ensure reliable connections without pre-punched holes, while the Inserter Machine 618MSPe Standard Press installs up to four fasteners per part with automatic adjustments and safety features.

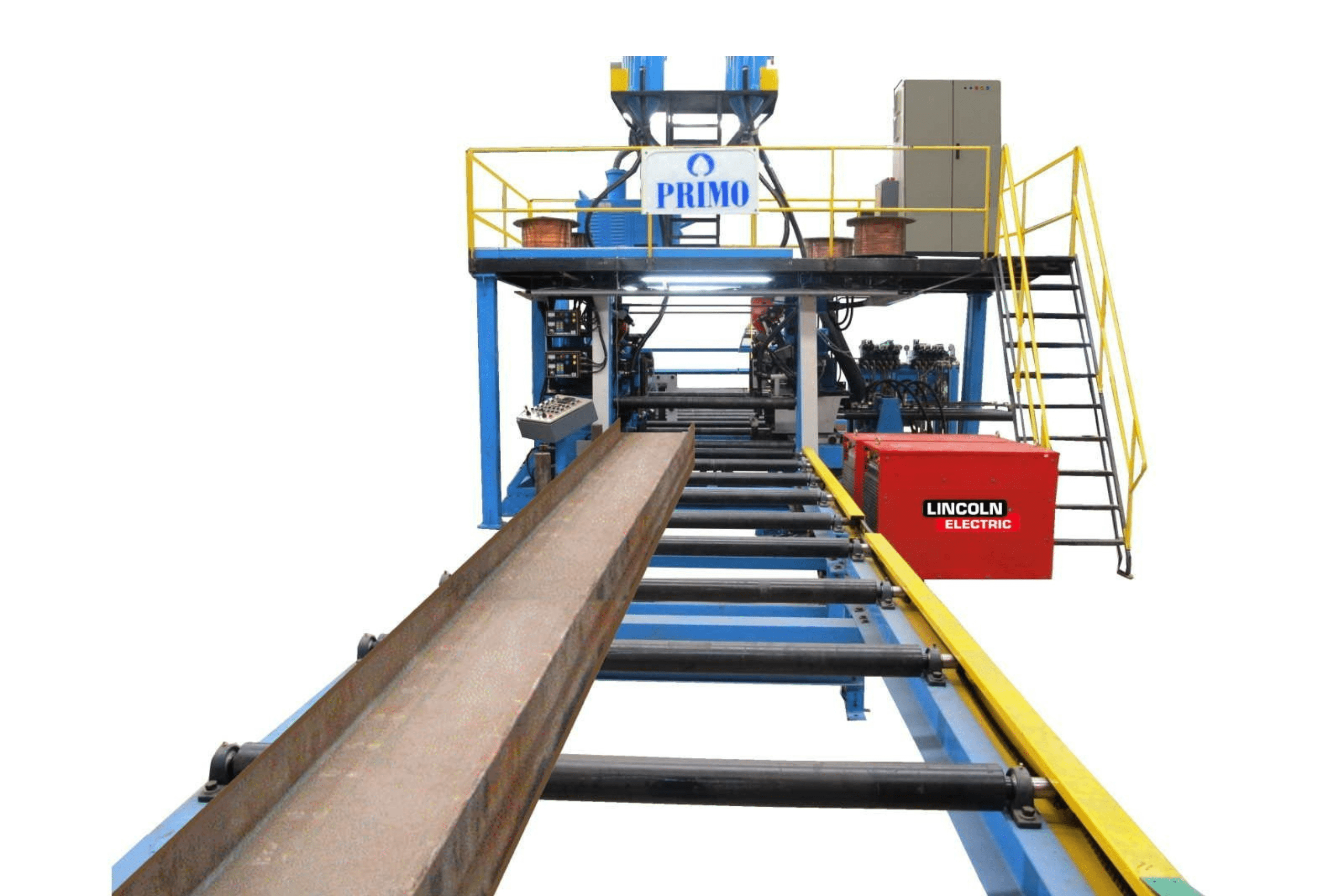

The Horizontal Automated Line (PRIMO ULTIMATE) and the Vertical Beam Assembly Line handle a wide range of dimensions from 160 mm to 2000 mm wide and thicknesses ranging from 4mm to 80 mm, producing high-quality beams and curved structures up to 18000 mm long and with radii as tight as 15000 mm.

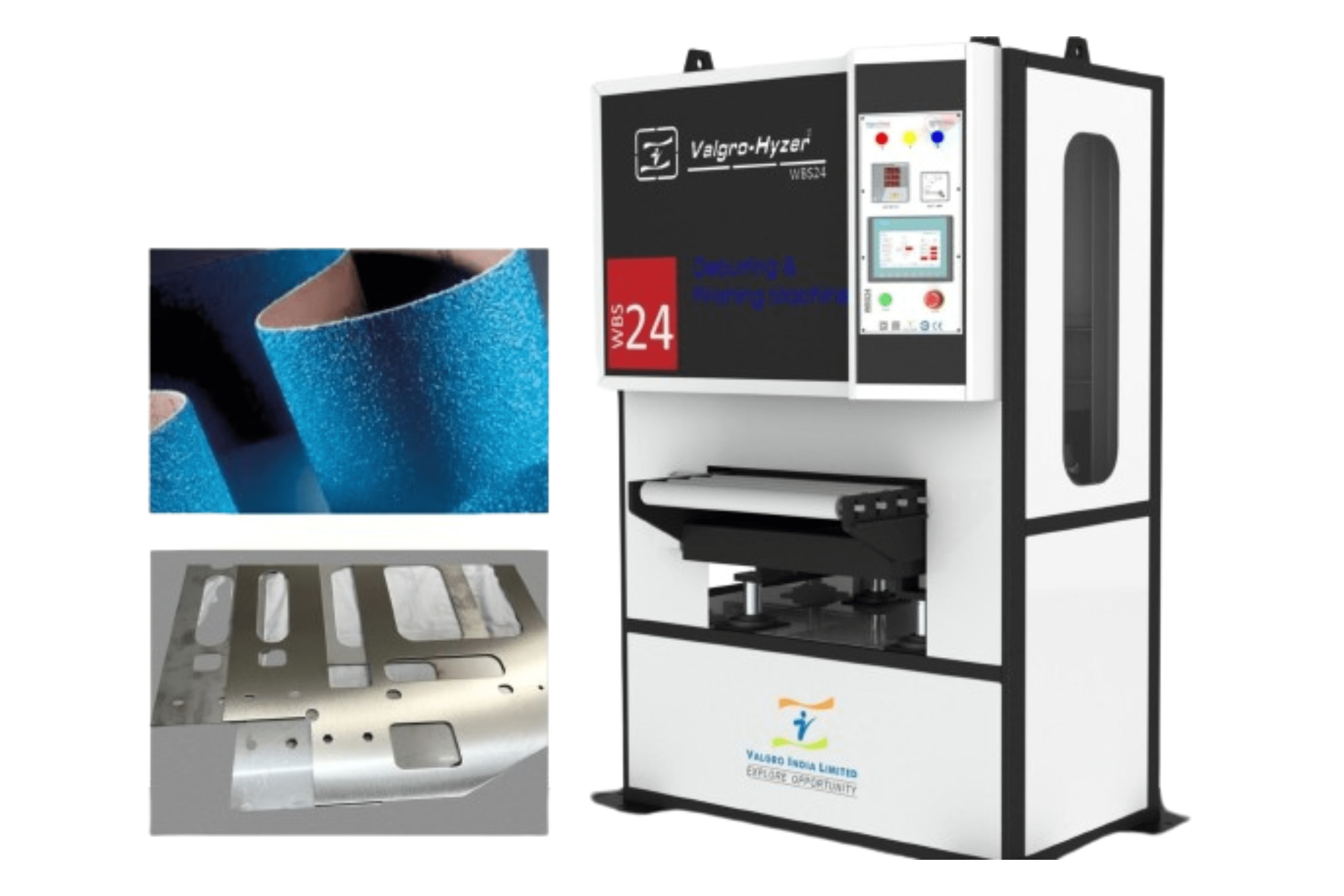

Deburring and Leveling:

The Valgro single-head deburring machine handles parts up to 25 mm thick and 600 mm wide, efficiently removing burrs for enhanced durability. The ERSM 800SRS double-head deburring machine, with roller brushes, processes materials up to 100 mm thick and 800 mm wide, offering uniform deburring and edge rounding. Additionally, the ERSM Manual Precision Leveling Machine flattens critical metal parts with 19 rollers and a 4-layer system, ensuring high accuracy and quality standards.

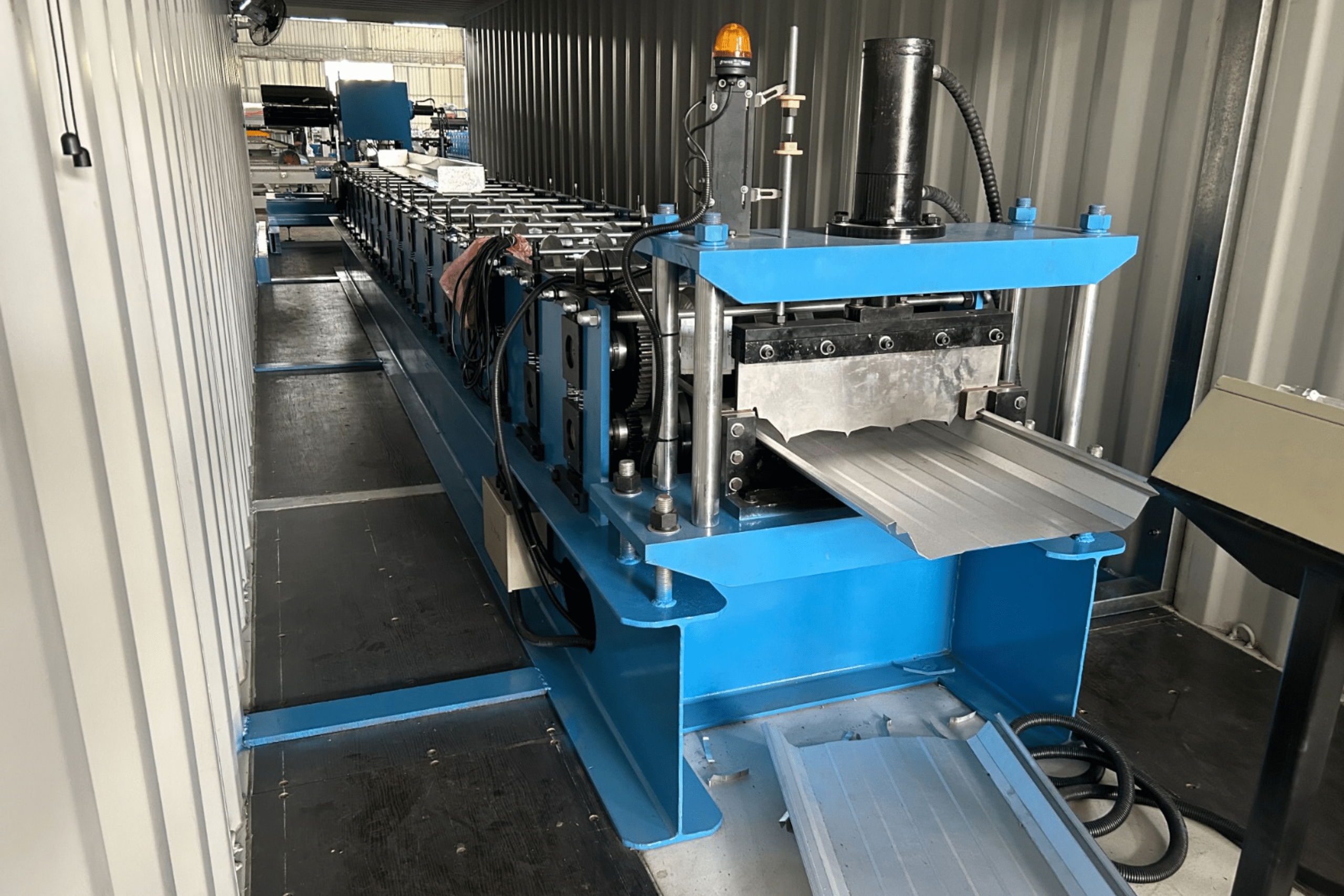

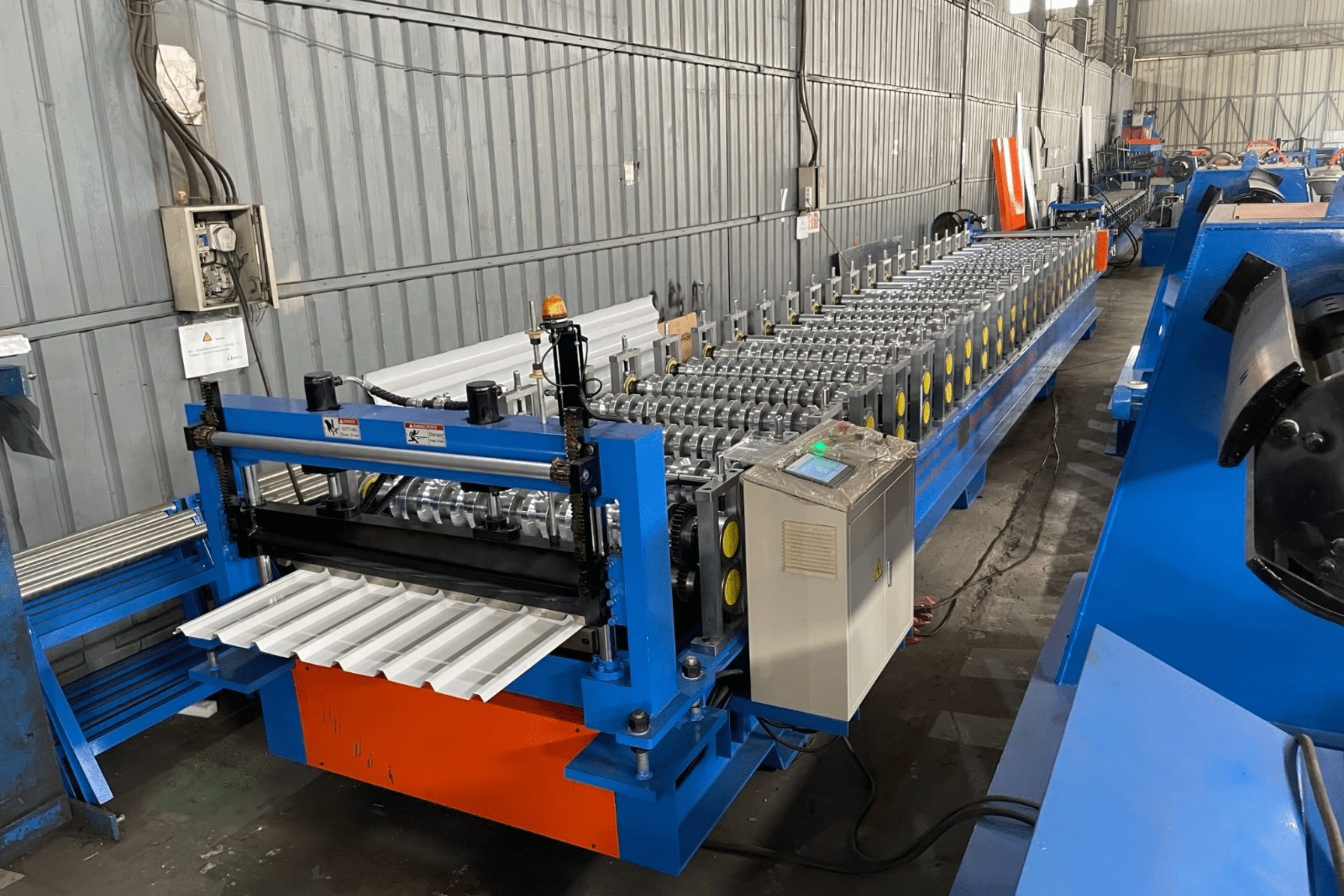

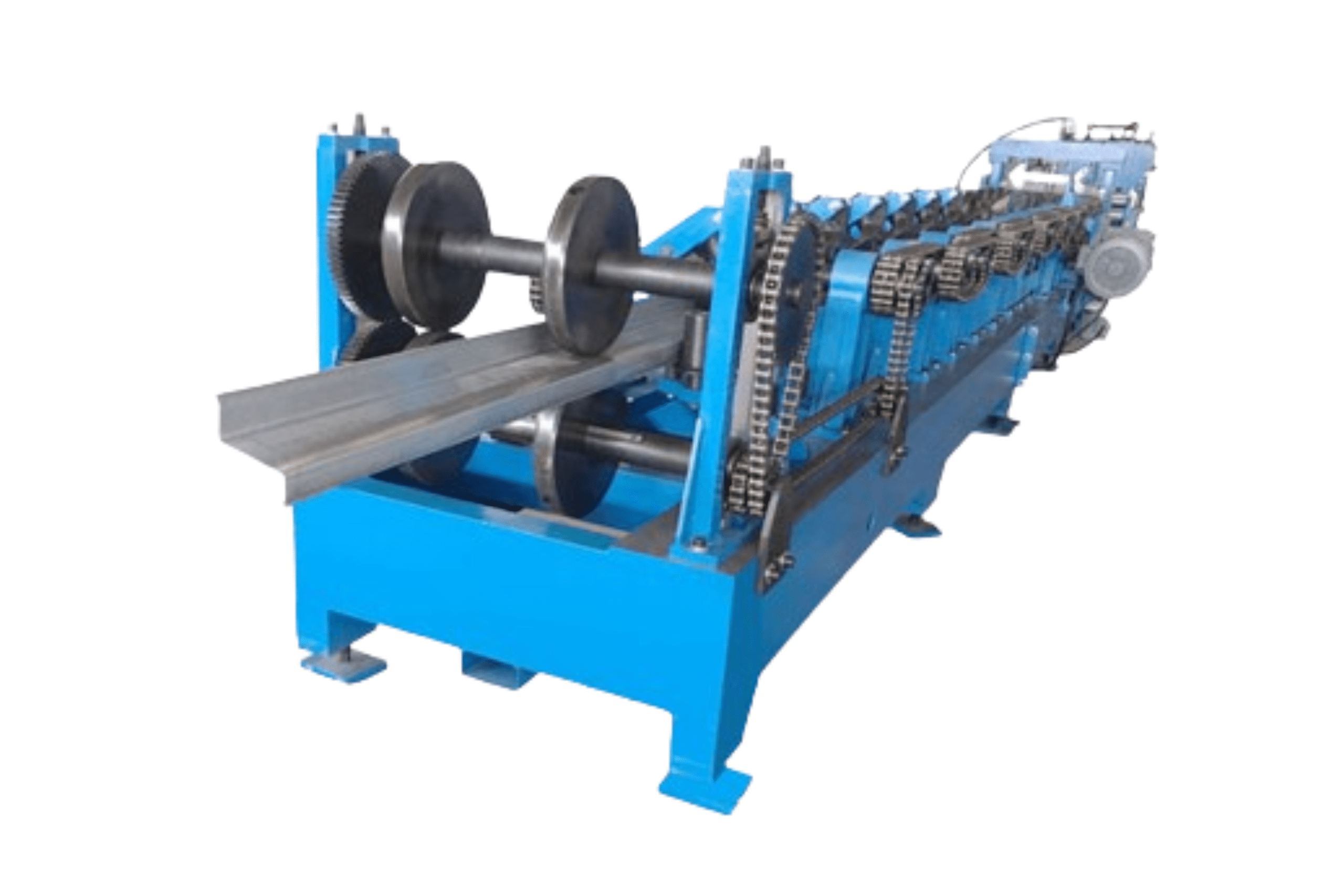

Forming Systems:

For forming and sheet processing technology we use gear-driven, PLC-controlled machines for C/Z purlins (80-300 mm width, 40-85 mm height) with thicknesses of 1.2 to 3.0 mm, processing GP, CR, HR, and HRPO steel. Our sheet forming machine handles widths up to 1220 mm and thicknesses from 0.47 mm to 0.7 mm for BARE GALV, PPGL, and PPGI steel. The SSR forming machine processes sheets up to 610 mm wide and 0.47-0.7 mm thick, using similar steel types.