Cnc And Press Shop

Precision Cutting, Dynamic Bending, The Right Way!

Equipped with machines that ensure precision and efficiency in manufacturing high-quality components.

Our CNC and Press shop facility features advanced machinery and technology that deliver precise and efficient metal forming. Equipped with high performance CNC machines and versatile Press brakes, we produce high-quality components with accuracy. Our streamlined processes and rigorous quality control ensure reliable results for various manufacturing requirements.

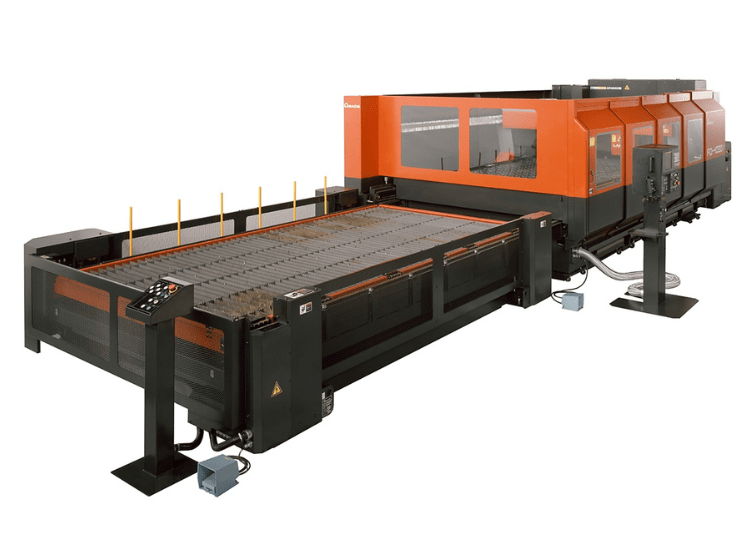

Laser Cutting Machines:

Our laser cutting capabilities are supported by a range of advanced machines designed to deliver high precision across various materials. We operate with different types of laser cutting system for sheet size of 1500 mm X 2500 mm and a tube cutting laser for stork length of 650 mm.

Fiber Laser Machine – 6 KW (JFY – A Member of Trumpf Group): Machine excels in cutting mild steel (MS) up to 25 mm thick, stainless steel (SS) up to 20 mm thick, and aluminum (Allu.) upto 20 mm thick. It provides exceptional speed and accuracy for complex designs.

Fiber Laser Machine – 6 KW (AMADA): Revamped AMADA fiber laser cuts mild steel up to 25 mm, stainless steel up to 20 mm, and aluminum up to 20 mm with precise results.

CO2 Laser Machine – 4 KW (AMADA): Machine is versatile in cutting mild steel up to 20 mm, stainless steel up to 16 mm, and aluminum up to 12 mm. It is particularly suited for applications requiring high-quality surface finishes.

Fiber tube cutting Laser Machine – 2 KW: A multi-functional machine; Cutting round tube of outer dimension 15mm up to 100mm and square tube of outer dimension 15mm up to 80 mm.

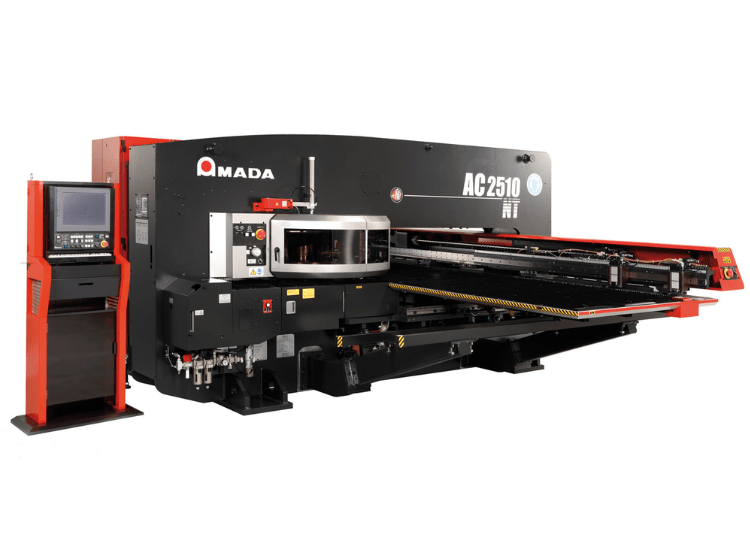

Turret Punch Press:

Our punching and press capabilities include several advanced machines that enhance our metal forming processes.

AC 2510 – 20 Ton (AMADA): This punching machine handles mild steel up to 4 mm and stainless steel up to 2 mm. It supports sheets up to 1250 X 2500 mm, with an option for extended cutting sizes through repositioning.

EM 2510 – Servo Drives (AMADA): Another versatile punching machine, it features servo-driven technology for high precision and efficiency, processing similar thicknesses and sizes as the AC-2510.

MT 300 E – Servo Drives (JFY A Member of Trumpf Group): This 30-ton punching machine with auto loading and unloading capabilities is equipped for cutting mild and stainless steel up to 6 mm thick and supports sheets up to 1500 X 2500 mm with repositioning for larger sizes.

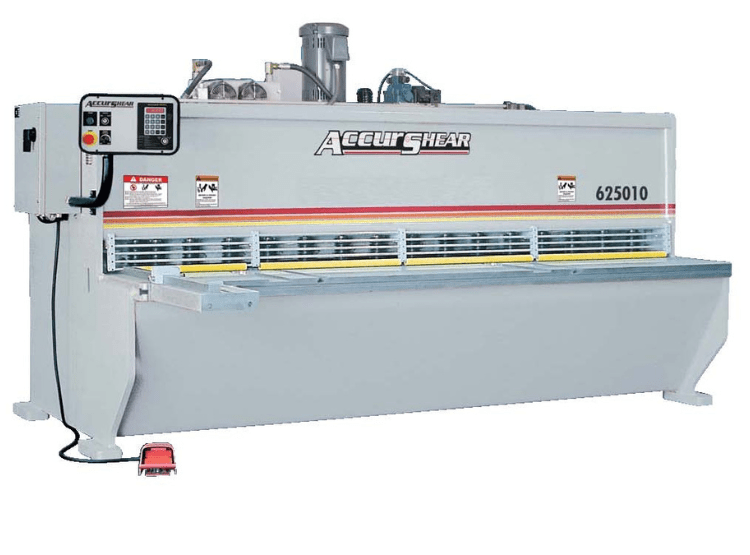

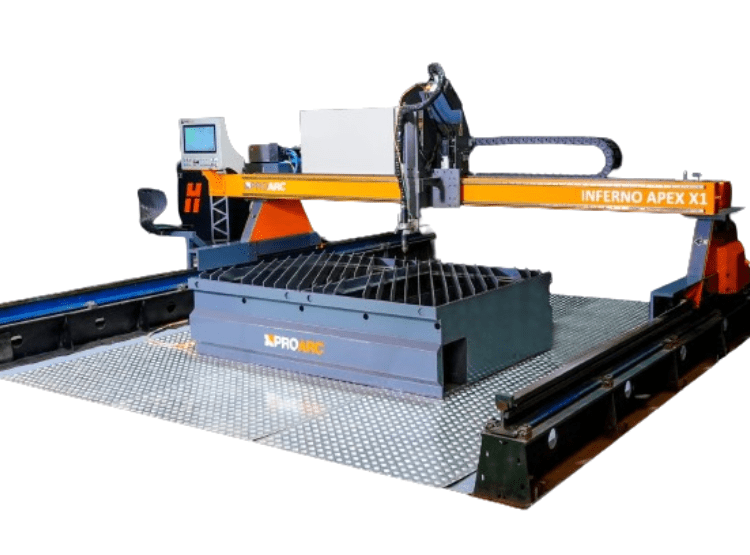

CNC Cutting Machine:

Our CNC cutting system is designed for flexible and precise profile cutting.

Inferno-Ultimo (Pro-Arc): Equipped with the MaxPro 200 Hypertherm USA plasma source. This advanced CNC plasma cutting machine excels in handling a cutting width of up to 4200 mm and a length of 13000 mm. It is versatile in cutting materials, with a maximum thickness of 32 mm for mild steel (MS) and 25 mm for stainless steel (SS), including edge cutting capabilities of up to 50 mm for MS and 45 mm for SS. The machine utilizes plasma gas (O2, Air, N2) and shield gas (Air, N2) to achieve high-speed, precise cuts. It boasts a positioning accuracy of ±0.5 mm/m and a repositioning accuracy of ±0.2 mm/m, making it highly suitable for complex and large-scale projects with minimal distortion.

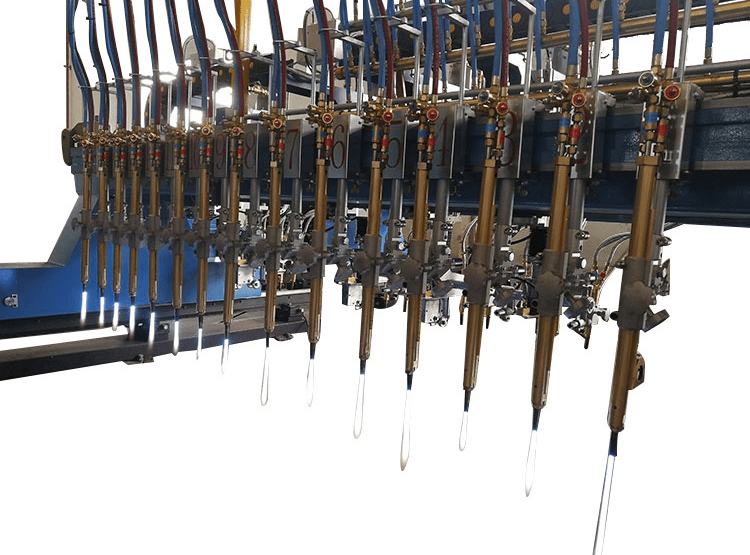

Oxy-Fuel Gas Cutting: The machine offers exceptional profile cutting capabilities, handling up to 100 mm thickness of mild steel. It operates using a combination of oxygen with either acetylene or LPG as fuel gas. The system can effectively cut materials with a width of up to 4000 mm and a length of 12000 mm. It is engineered for high performance, with a positioning speed of up to 10 meters per minute and a positioning accuracy of ±0.5 mm/m, while repeatability is maintained at ±0.2 mm/m. Equipped with a single Harris oxy-fuel torch, this system ensures high-quality cuts that conform to ISO 9013 standards, providing precise and reliable results for various cutting applications.

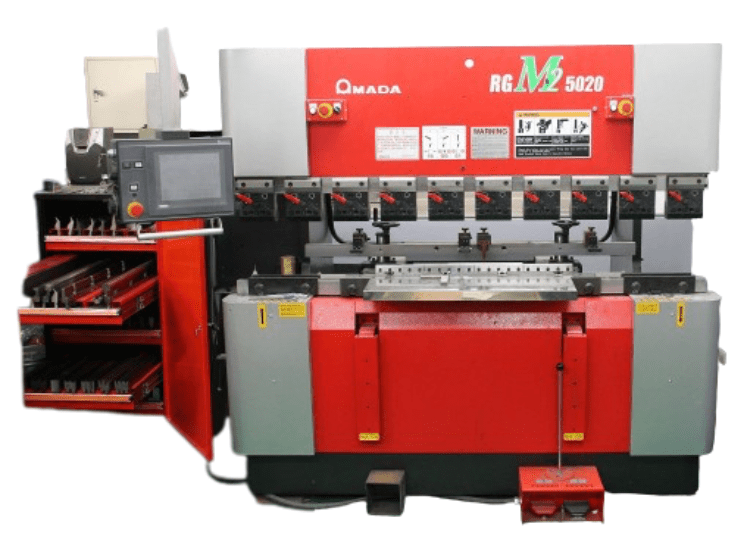

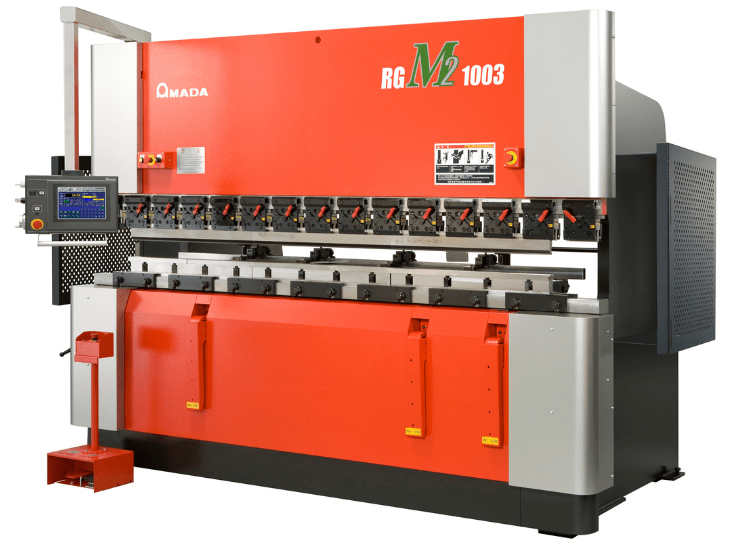

Press Brake Machines

Bending services across a range of materials, accommodating sheet sizes up to 1250 x 2500 mm, with an extended capability of up to 4000 mm through repositioning. These machines can handle bending lengths of up to 6 meters and thicknesses up to 10 mm, providing exceptional precision and flexibility in metal forming.

We utilize several advanced press brake models, including the AMADA RGM2 3512, AMADA RGM2 5020, AMADA RGM2 8024, AMADA HDS 2204, ERSM 8024, and the ERSM 130 + 130 – 6 Meter tandem press with a follower.

Our precision forming services encompass a broad spectrum of materials, such as steel, aluminum, galvanized and stainless steel, and copper. Equipped to meet diverse fabrication requirements, we ensure high-quality metal components that are precisely tailored to your project specifications.